Building waterproofing scheme

The all-round waterproof way, an extraordinary waterproof experience.

Metal materials (color steel tiles, aluminum, stainless steel, iron doors), glass, lighting tiles, aluminum-plastic panels, sunlight panels, stone, coils, coatings, equipment bases, concrete and other base surfaces have been widely spread throughout the country. It is the best metal roof waterproof system used today.

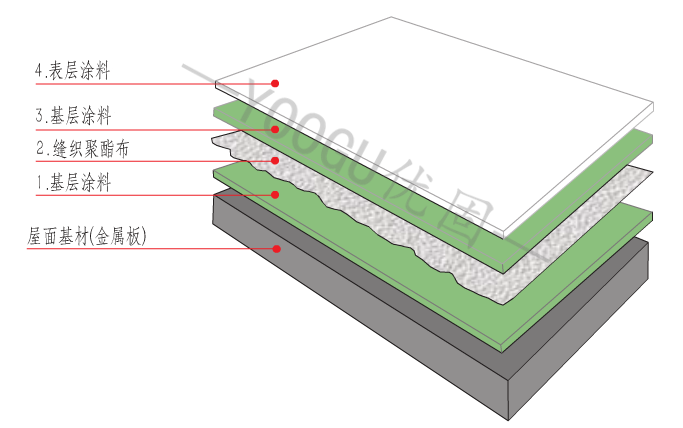

YOOGU metal roof waterproof system is composed of base layer, surface layer waterproof coating and stitched polyester fabric. After the waterproof coating is cured, it becomes a seamless high-elastic waterproof system. The waterproof material adopts 100% pure acrylic emulsion as the base material, and is made of high-quality waterproof materials. The high-quality waterproof coating is specially designed for various types of roofing and local waterproofing. , Process performance ranks first in the world. The waterproof system is easy to construct and safe, and does not require professional equipment. After construction by professionals, it will form a durable and energy-saving roof seamless waterproof system, which can maintain long-term elasticity in various harsh environments and can extend the service life of the roof for more than 30 years.

Weather resistance: It can be widely used in the temperature environment of -55℃~+88℃, and maintain good elasticity for a long time.

Anti-aging, chemical corrosion: no change in laboratory artificial aging performance test for 3000 hours, equivalent to 30 years of natural aging. Can effectively resist the erosion of chemicals and industrial exhaust.

Tensile and tear resistance: excellent tensile and tear resistance, can effectively follow the physical structure changes of the base surface, especially suitable for base surface deformation, cracking and waterproof protection of expansion joints, make up for cracks up to 2mm.

Adhesiveness: It has strong adhesive force and is evenly integrated with the base surface, achieving 100% continuous full staining, without channeling water, forming a skin-type seamless waterproof system.

Breathability: Residual moisture on the base surface can be evaporated through the coating.

Anti-mildew and anti-bacteria: excellent long-term anti-mildew and anti-bacterial, moisture-proof performance. A durable and energy-saving roof seamless waterproof system can maintain the elasticity for a long time under various harsh environments and can extend the service life of the roof for more than 30 years.

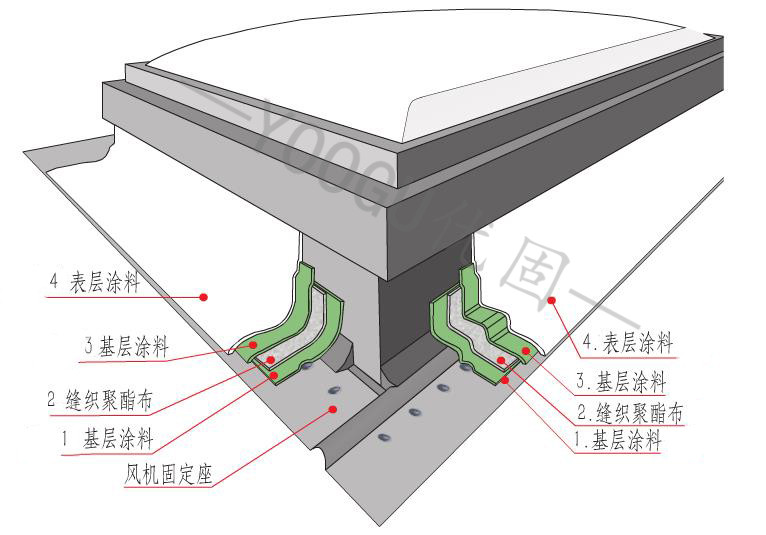

1.Construction node:

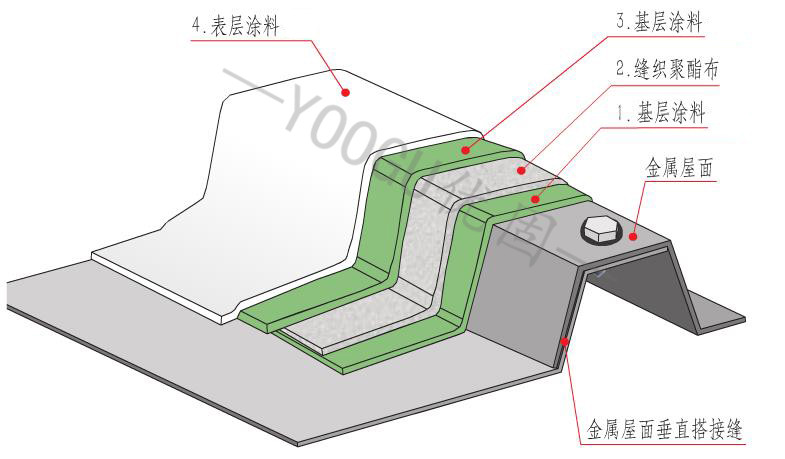

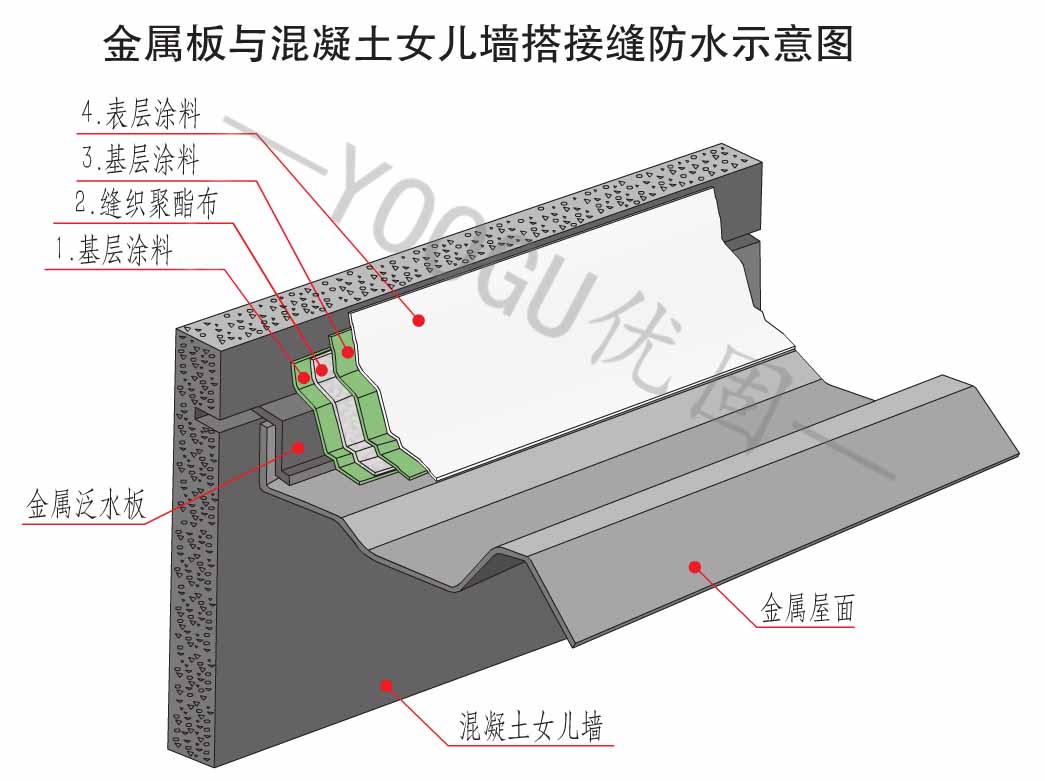

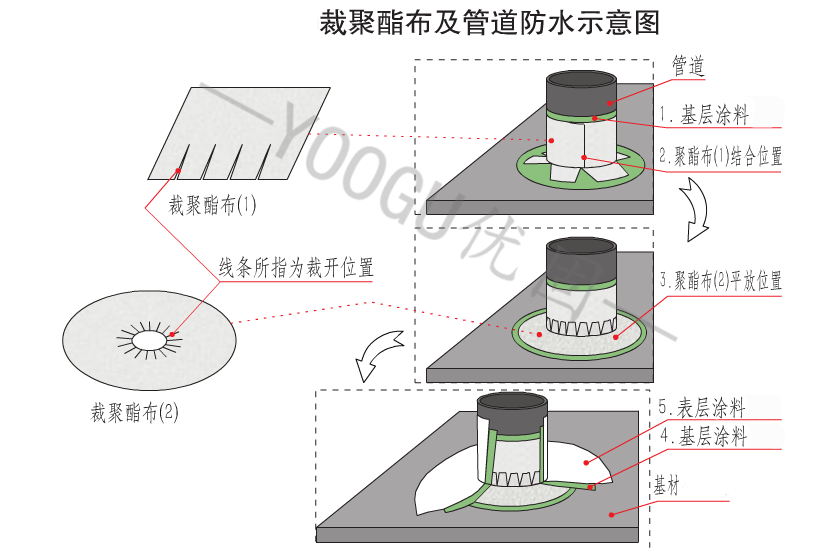

The parts of the metal roof that need to be waterproofed are: vertical laps, horizontal laps, laps on both sides of the ridge, around the lighting tiles, around the fans, around the chimney pipes, vents, all screws on the roof, sinks, joints on the parapet wall, etc. Suspicious parts of the seam, or the whole roof is covered with waterproof.

2.Waterproof width:

Determine the parts to be waterproofed and the width of the waterproof layer, and cut the reinforced polyester cloth of the corresponding width.

The width of the waterproof layer, the area of the waterproof layer of the screw is generally 0.01 square meters (10cm×10cm);

The width of the horizontal lap waterproof layer is 20cm; the width of the vertical lap waterproof layer is 15cm; the width of the waterproof layer on both sides of the ridge is 20cm, etc. The width of the waterproof layer is best determined according to the height of the roof tile peak on site and the construction requirements .

3.Pretreatment:

1) Identify the roof that requires waterproof construction. Before the waterproof construction, first carefully clean the roof color steel plate. You must ensure that the base surface firmware is free of looseness, oil, dust, and clear water to keep it clean;

2) Patch and repair the perforated and damaged parts of the color steel plate, and correct and restore the color steel plate with warped edges, so that the whole roof is smooth, without damage and no warpage;

3) Repair and strengthen the screws that the color steel plate has fallen off to make them tight without looseness.

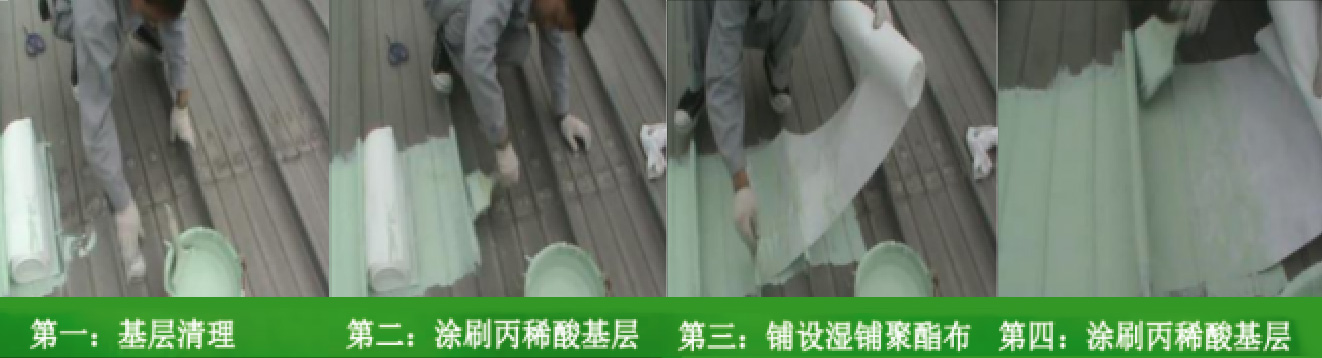

4. Construction method (three coats and one cloth):

Identify the area to be waterproofed and clean the base surface to keep the water-proof parts free of oil, dust and rust.

One coat: On the cleaned base surface, apply a metal roofing acrylic base waterproof coating.

One cloth: When the coating is still wet, lay the polyester cloth directly on the coating, use a brush to flatten and compact it, to ensure that the polyester cloth is not bubbly and not over wrinkled, and the width of the polyester cloth is about 5-10 cm.

Second coating: Then apply acrylic roofing waterproof coating of metal roofing on the polyester cloth, so that the coating and the polyester cloth are completely saturated to dryness.

Three coats: After the above two coats and one cloth are dried and solidified, then apply a metal roofing acrylic surface waterproof coating together, and it can be accepted after being dried (surface adjustable color).

Company switchboard: 0755-89212007

Fax: 0755-89212007

E-mail: shili.yuan@yougufangshui.com

Company address: Qichuang Low Carbon Park, No. 1034, Longgang Avenue (Pingdi Section), Longgang District, Shenzhen