Building waterproofing scheme

The all-round waterproof way, an extraordinary waterproof experience.

Factories, garages, electroplating plants, battery plants, chemical plants, chemical storage areas, large water tanks, electrolytic cells, wastewater treatment, etc.

The anti-corrosion floor paint is a three-component paint, suitable for anti-corrosion tanks, heavy machinery surface treatment and the floor of corrosion-prone areas of chemical enterprises, anti-corrosion engineering of oil industry and chemical tanks of sewage tanks, etc. It has strong resistance to penetration, resistance to strong acids, alkalis, salts and various organic solvents. It has high surface hardness and good compactness. This paint is divided into two groups, A and B, of which group A is epoxy amine curing agent, group B is composed of epoxy paint and glass powder. The paint is resistant to strong acids and alkalis, sea water, salt spray and various chemical media, strong adhesion, wear resistance, impact resistance, dust resistance, etc. Mainly suitable for coating chemical plants, pipelines, electroplating plants, marine equipment, etc.

Strong adhesion, tensile crack resistance, can withstand long-term rolling of forklifts and trucks;

Make the ground resistant to corrosion, strong acids and alkalis, chemical solvents, impact, and cracks on the ground;

It can reach the original standard of the Ministry of Chemical Industry of China, chemical equipment, pipelines, corrosion resistance, no bubbles;

Increase the thermal deformation temperature and reduce the temperature impact strength;

In particular, it can improve the strength and elasticity of the substrate.

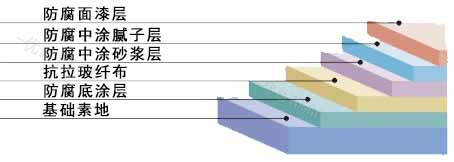

1. Basic treatment: polish, repair, remove dirt and dust according to the ground conditions;

2. Primer coating: use a strong primer with high permeability and adhesion to roll coat, to enhance surface adhesion and to close the moisture and moisture of the foundation ground, avoid the shell and delamination of the rabbit base layer and the epoxy coating;

3.Glass fiber cloth and medium coating construction: first spread glass fiber cloth and then apply anti-corrosion mortar to coat, each layer is coated in a layer of anti-corrosion mortar, until the thickness specified by the thickness of the glass fiber anti-corrosion floor until;

4. Putty layer: Use epoxy anti-corrosion intermediate coating material to mix quartz sand or double fly powder to scrape the putty layer, and construct two or three layers as required.It is required to achieve smoothness and no holes, so as to apply surface I;

5 Anti-corrosion surface coating: Two coatings with anti-corrosion top coating resin compound or color paint; Note: The resin used depends on the design, after the coating is finished, the toothed rolling hole is used to defoam;

6. During the construction of glass fiber anti-corrosion floor, pay attention to the proportion of materials, as well as the method of mixing materials and the time of mixing, to avoid the occurrence of a large number of bubbles in the chemical reaction of the anti-corrosion materials when adding additives, which increases the difficulty of construction. It takes a lot of time to defoam with toothed rolling holes.Another situation is that when the material is stirred unevenly, bubbles are generated after painting, and the surface effect of the surface layer will be affected after curing;

7. Topcoat construction: apply the prepared topcoat evenly with a trowel or roller. After completion, the overall ground is bright and clean, the color is uniform, and there is no empty drum;

8. Heavy-duty anti-corrosion topcoat: repeat the formulated topcoat several times to achieve heavy anti-corrosion effect;

9. Construction is completed: 24 hours before you can get on, 72 hours before heavy pressure. (25 degrees prevails, the low-temperature opening time needs to be moderately extended).

Construction Notes

1. The ambient temperature at the construction site should be higher than 5°C and the relative humidity should be less than 85% before construction.

2. The constructor should make actual records of the construction site, time, temperature, relative humidity, floor surface treatment, materials, etc. for reference.

3. After the paint is applied, relevant equipment and tools should be cleaned immediately.

Company switchboard: 0755-89212007

Fax: 0755-89212007

E-mail: shili.yuan@yougufangshui.com

Company address: Qichuang Low Carbon Park, No. 1034, Longgang Avenue (Pingdi Section), Longgang District, Shenzhen