Building waterproofing scheme

The all-round waterproof way, an extraordinary waterproof experience.

It is suitable for environmental areas with high wear resistance and high pressure resistance, such as stadium grounds, school playground grounds, garage floors, office floors, medical unit floors, home community road floors, and industrial plant floors.

Epoxy floor paint has the characteristics of strong acid and alkali resistance, abrasion resistance, pressure resistance, impact resistance, mildew resistance, waterproof, dustproof, anti-slip, antistatic, electromagnetic wave and other characteristics, good adhesion, and the coating does not crack or fall off , Bright and diverse colors, smooth and neat appearance, easy to clean and maintain. It uses a one-time coating process, no matter how large the area is, there are no joints, and it is still a kind of dust-free material, which has strong adhesion, abrasion resistance, and strong hardness.

It has seamless dustproof, easy to clean, acid and alkali resistance, mildew resistance and other excellent properties;

Beautiful and bright, seamless dustproof, easy to clean, easy to maintain,

Strong adhesion to the base surface, small shrinkage, wear resistance and durability;

Strong adhesion, good flexibility and impact resistance;

Reinforcing the strength of the substrate, can provide excellent adhesion;

Various colors, a variety of colors are available for customers to choose;

Fast construction and economical cost.

1. Pretreatment of base surface: Before construction, ensure that the base surface is flat, naturally dry, free from attachments, free of C and cracks, etc.

2. For defects, the base surface strength must be above C25 for construction.

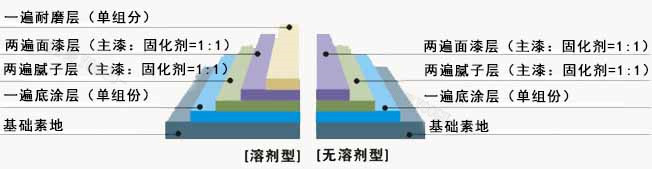

3. Primer coating: Use solvent-based epoxy single-component primer or solvent-free epoxy primer (primary paint: curing agent = 5:1) to mix and mix evenly; use a roller and brush to evenly paint , No missing coating.

4. Putty layer: use solvent-based epoxy paint (1:1) or solvent-free epoxy paint (5:1) mixed in proportion and add appropriate fillers (such as quartz powder, talc powder) to mix evenly; use batch knife batch Including 1-2 times, the focus is to fill the hole defects on the ground; after curing, polish the defects such as the knife marks, clean them with a vacuum cleaner, feather duster, wringed wet towels, etc.

5. Topcoat: Use solvent-based epoxy topcoat (1:1) or solvent-free epoxy topcoat (5.1) mixed in proportion and stir evenly; dip the topcoat with a prepared roller and roll evenly. The coating is required to be uniform, without omission, and roll-coated twice.

6. Wear-resistant layer: This process can be used according to the needs of users; after 12-24 hours of application I, that is, after curing to the pedestrian without leaving a mark, the epoxy floor wear-resistant layer paint is newly applied by roller coating, which can greatly Improve floor finish and durability.

Note: If your workshop or plant often walks with heavy machinery such as forklifts, we recommend that you use epoxy resin mortar type floors.

Company switchboard: 0755-89212007

Fax: 0755-89212007

E-mail: shili.yuan@yougufangshui.com

Company address: Qichuang Low Carbon Park, No. 1034, Longgang Avenue (Pingdi Section), Longgang District, Shenzhen