Building waterproofing scheme

The all-round waterproof way, an extraordinary waterproof experience.

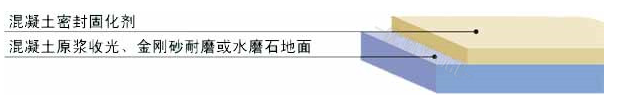

Coagulation: soil hardening, wear-resistant, dust-proof, sealed and cured floor is suitable for any indoor and outdoor environment that requires clean, dust-proof, easy to clean, hard, highly wear-resistant, weak resistance. Flat old and new concrete with high requirements for chemical erosion and impermeability Surface, emery wear-resistant floor, terrazzo floor, stone and other base surfaces, such as underground parking lots, highways, factories, shopping centers, warehouses, parking lots, service stations, hangars, freight distribution yards and other areas.

Coagulation hardening wear-resistant sealing and curing floor, is a liquid environmental protection, water-based floor material; is a penetration, sealing, hardening material; is a penetration, sealing, hardening material; can penetrate into the coagulation The compound and the semi-hydrated cement, free calcium, silicon oxide and other substances contained in the coagulated coagulant undergo a series of complex chemical reactions to produce a hard substance. These final compounds will make the surface of the coagulator dense The degree is improved, so as to improve the strength, hardness, wear resistance, impermeability and other indicators of the concrete surface.

The final product of complex chemical reactions will clog and increase the structural pore strength of the sealed concrete (corundum floor, terrazzo floor) to increase the surface hardness, and the increase in the density to improve the impermeability. The path to reduce the flow of water is to reduce the intrusion of harmful substances, thereby greatly enhancing the resistance of concrete (corundum floor, terrazzo floor) to the resistance of chemical substances. Therefore, coagulant seal curing agent can bring long-term sealing, strong, wear-resistant, dust-free concrete (diamond floor, terrazzo floor) surface layer.

Hard and wear-resistant: the best can improve the Mohs strength to 8-9 degrees.

Effective sealing: Insulates solid and liquid impurities from entering concrete.

Resistant to chemical attack: inhibits chemical substances from entering concrete.

Completely dust-proof: Improve the surface compactness and effectively prevent the dust on the concrete surface.

Good anti-aging property: no yellowing and anti-whitening phenomenon. The general service life is 15-20 years.

Breathing function: Allow gas and liquid to circulate freely to avoid peeling and micro-cracks on the ground.

Long gloss: The hard ground continues to rub during use, the brighter the more it is used.

Simple maintenance: simple cleaning, no waxing, reducing high maintenance costs.

Safety and environmental protection: colorless, odorless, non-toxic, water-based environmentally friendly products.

Strong penetrability: excellent penetrability, permeable concrete 5-8mm.

1. Sanding the base surface: Use a professional sanding machine to use a 100-mesh resin disc for full sanding (you can use wet water for wet treatment) to expose the clean and fresh surface of the concrete.

2. Clean the base surface: clean up the dirt generated by the grinding. If the water is used for ground grinding, the accumulated water needs to be cleaned up.

3. Spraying material: Use concrete to seal the curing agent and spray it evenly on the polished ground (amount per square: 0.4kg-0.5kg), and fully react for 2-4 hours.

4. Wash the base surface: When the surface begins to become sticky, wet the ground with clear water for about 2 hours, then remove all the clear water and dry naturally for more than 12 hours.

5. Preliminary polishing: After the ground is completely dry, perform the ground polishing work. First, use a 300-mesh epoxy resin professional sanding machine to perform a full polishing (2-3 times) to perform preliminary polishing on the entire base surface.

6. Comprehensive polishing: Use a 500-1000 mesh epoxy resin professional grinding machine for comprehensive fine grinding (2-3 times) to fully polish the entire base surface.

Before and after construction:

Company switchboard: 0755-89212007

Fax: 0755-89212007

E-mail: shili.yuan@yougufangshui.com

Company address: Qichuang Low Carbon Park, No. 1034, Longgang Avenue (Pingdi Section), Longgang District, Shenzhen