Yougu waterproof coating Tixol

The all-round waterproof way, an extraordinary waterproof experience.

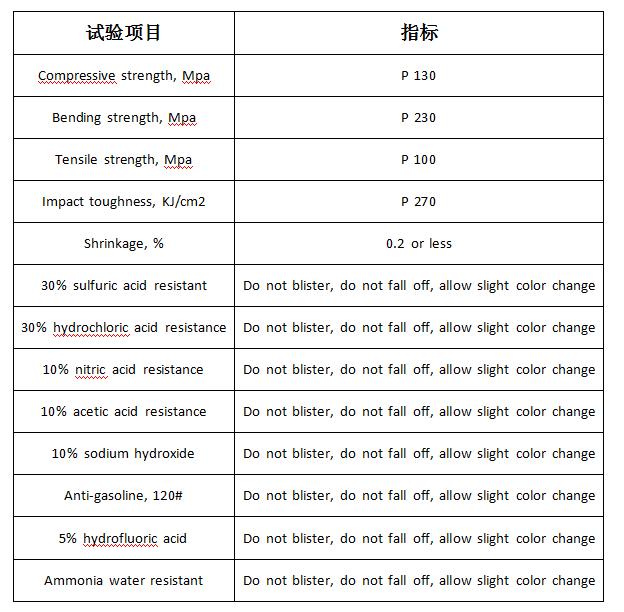

Anticorrosive floor paint is a three-component paint, suitable for the surface treatment of corrosion tank, heavy machinery surface treatment and chemical enterprise easy to corrode area, petroleum industry corrosion protection engineering and sewage pool chemical pool, etc. Strong anti-permeability, strong acid, alkali, salt and various organic solvents, high surface hardness and good compactness. This paint is divided into two groups: A and B, and group A is the epoxy curing agent, and group B is composed of epoxy paint and glass powder. The paint is resistant to strong acid and alkali, salt water, salt mist and various chemical dielectric corrosion, strong adhesion, abrasion resistance, impact resistance, dust proof and so on. It mainly applies to chemical plant, pipeline, electroplating plant, Marine equipment and other coating.

Strong adhesion, anti-lacing, forklift truck and truck;

The ground is resistant to corrosion, strong acid and alkali resistance, chemical resistant solvent, impact resistance, anti-ground cracks;

Can meet the original Chinese chemical industry department standard, chemical equipment, pipeline, corrosion resistant, no air bubbles;

Increase the temperature of heat variation and reduce the temperature impact strength;

In particular, it can improve the strength and elasticity of the matrix.

Applicable to factories, garage, electroplating plant, battery factory, chemical storage area, large water tank, electrolytic pool, waste water treatment, etc.

1. Basic processing: polishing, repairing, removing dirt and removing dust based on ground conditions;

2. bottom coating: the roller coating permeability and strong adhesion primer, enhance the surface adhesion and closed ground moisture, moisture, avoid the base layer and epoxy coating shell, take off a layer;

3. Construction of fiberglass cloth and medium coating: spread fiberglass cloth first and then coat with anticorrosive mortar, each layer is coated with a layer of anticorrosive mortar, until it reaches the thickness specified by the thickness of glass fiber anticorrosive floor until;

4. Putty layer: use epoxy anticorrosive materials to prepare quartz sand or double-fly powder to scrape the putty layer and build two to three as needed to achieve the smooth and no holes and the construction of the surface.

5. Anticorrosive surface coating: using anticorrosive paint resin adhesive or color paint coating 2; Note: the resin is designed according to the design. After finishing, it is used to remove the cavity with teeth.

6. in the process of fiberglass anticorrosive floor construction, pay attention to material mixing ratio, and technique of mixing materials and mixing time, avoid corrosion materials react when it joined agents appear a large number of air bubbles, increase the construction difficulty, also spend a lot of time using a toothed roll foam, there is also a situation is, uneven when mixing materials, besmear to brush after the bubble, for curing will film surface of the surface effect;

7. Surface painting construction: the finishing coat is evenly coated with a trowel or roller, and the whole ground is bright and clean after finishing, the color is uniform, and there is no empty drum.

8. Heavy anticorrosive surface paint: the reformulated surface paint will be repeated several times to achieve the anti-corrosive effect;

9. Construction completion: 24 hours after the master, 72 hours before the pressure. (25 degrees, the low temperature opening time should be extended moderately).

Construction considerations

1. the construction site of the ambient temperature shall be higher than 5 ℃, relative humidity less than 85% before construction.

2. The builder shall make the actual records of the construction site, time, temperature, relative humidity, surface treatment of floor and materials, etc. to prepare for the examination.

3. After coating construction, the equipment and tools should be cleaned immediately."

Company switchboard: 0755-89212007

Fax: 0755-89212007

E-mail: shili.yuan@yougufangshui.com

Company address: Qichuang Low Carbon Park, No. 1034, Longgang Avenue (Pingdi Section), Longgang District, Shenzhen