News Center

The all-round waterproof way is an extraordinary waterproof experience.Steel structure roof waterproof structure defects and countermeasures

Foreword: For a long time, due to some factors of its own structure, color steel roof leakage is a common phenomenon. In addition, the high thermal conductivity and expansion coefficient of the steel roof make the temperature difference of the color steel plate on the roof in winter and summer very large. The gap between various joints and lap joints is not a normal state. Therefore, the waterproofing of steel roofs has not been well solved. The following is an analysis of the common structural defects and hidden dangers of steel roofs and the corresponding waterproof schemes.

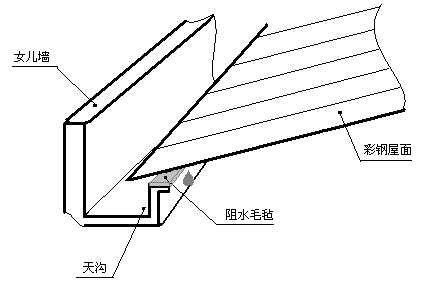

1. Waterproof structure and defects of color steel roof gutter

The structure of the color steel roof gutter is usually in the following form:

For some projects, the water-blocking felt in the picture above is not designed.

When the slope of the color steel plate is large enough, theoretically the rainwater flows along the color steel plate into the gutter instead of flowing out of the gutter. However, due to the large span of many roofs, considering the cost, a smaller slope is adopted. Under the influence of wind or the effect of airflow, very colorful steel plates at the junction of the gutter, rainwater will flow down the color steel plates. Phenomenon inside the house outside the gutter. In order to avoid this situation, some roofs are specially designed with a layer of felt at the joint between the gutter and the color steel plate when designing the steel structure, which is used to block the outflow of rainwater, that is, to block the flow of rainwater to the interior. Although this design can partially block the outflow of water, it cannot fundamentally solve the problem of water leakage. Moreover, as time goes by, the upper edge of the gutter will rust and wear through under the action of the accumulated felt.

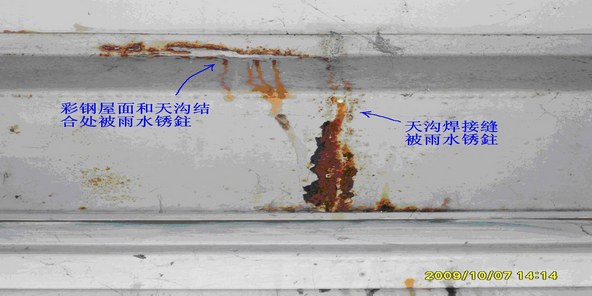

Picture of a construction site:

In the picture, we can see from the back of the gutter: the inner and upper edges of the gutter have been rusted and accompanied by a lot of water stains; the gutter welding seam has been rusted and leaking under the soaking of rainwater (note the weld Water droplets at the place) This shows that the traditional structural waterproofing cannot achieve the perfect waterproof effect, especially when the old roof is maintained or waterproofed, this structural structure brings a lot of inconvenience to the subsequent work.

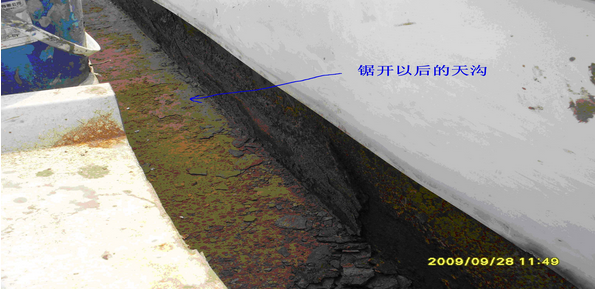

The following picture is the shooting situation of the gutter roof:

In the above picture, the original design idea is to make the gutter as little as possible to overcome the influence of wind or airflow on rainwater, so that the water flows smoothly into the gutter. However, judging from the actual effect, the waterproof effect is not good, and it affects the cleaning and maintenance of the gutter.

Gutter after sawing (photographed after dirt is removed):

It can be seen from the figure that this semi-closed gutter cannot be maintained and cleaned, and the dirt inside blocks the water channel, which makes the gutter very rusty. Its service life is greatly shortened.

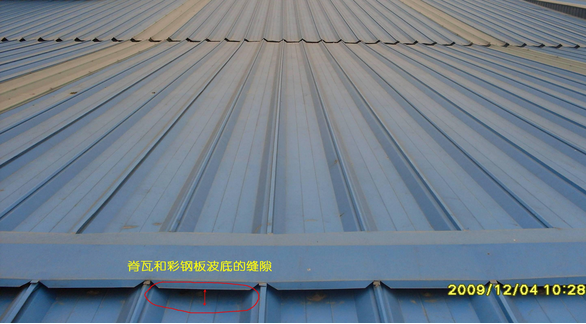

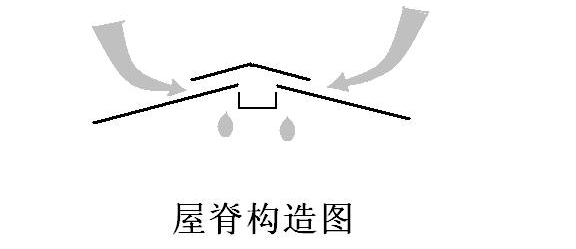

2.Color steel roof structure and waterproof defects

Due to the angles (wave crests) of the color steel plate, the ridge tile cannot be close to the wave bottom of the color steel plate, which causes a certain gap between the color plate wave bottom and the ridge tile. As mentioned in the previous section, under the influence of wind, rainwater will flow indoors along this gap. Therefore, some steel structures are designed with a small gutter under the ridge tiles and color steel plates. Practice has proved that even with this built-in gutter, the waterproof effect is still limited.

According to on-site observations, rainwater usually flows down the back of the color steel plate, and the actual role of the built-in gutter at this time is very limited. Especially for sandwich color steel plates, rainwater will penetrate down along the foam board or rock wool, causing the entire color steel plate to not know where it will leak. This brings a lot of unnecessary illusions and delays to the waterproof leak detection work.

summary:

Even for a newly constructed color steel roof, the gutter and the ridge are its weaker links. In the future, the problem of waterproofing will actually be in front of us the moment it is completed. In addition to some of the situations analyzed above, we can also find that there is almost no slope in the gutter, and the long-term accumulation of dirt will cause local blockage, and rainwater will accumulate in certain parts of the gutter for a long time, so rust moth is inevitable of. If the blockage is severe, during heavy rain, rain water may overflow the gutter, which is unimaginable. In addition, the gutter drain is also a weak link in waterproofing.

In addition, the horizontal joints, vertical lap joints and other node links of the color steel plate are all as described in the preamble, and various abnormal gaps (caused by temperature differences) will appear. Using conventional waterproof leak-proof methods, For example, silicone sealant, waterproofing membrane, and asphalt cannot effectively cure the leakage problem for a long time. The biggest weakness of these conventional materials is poor weather resistance, which cannot withstand long-term large temperature drop changes. In the picture below, a project used silicone rubber waterproof construction in the same period of construction, but it has no effect on several leaks.

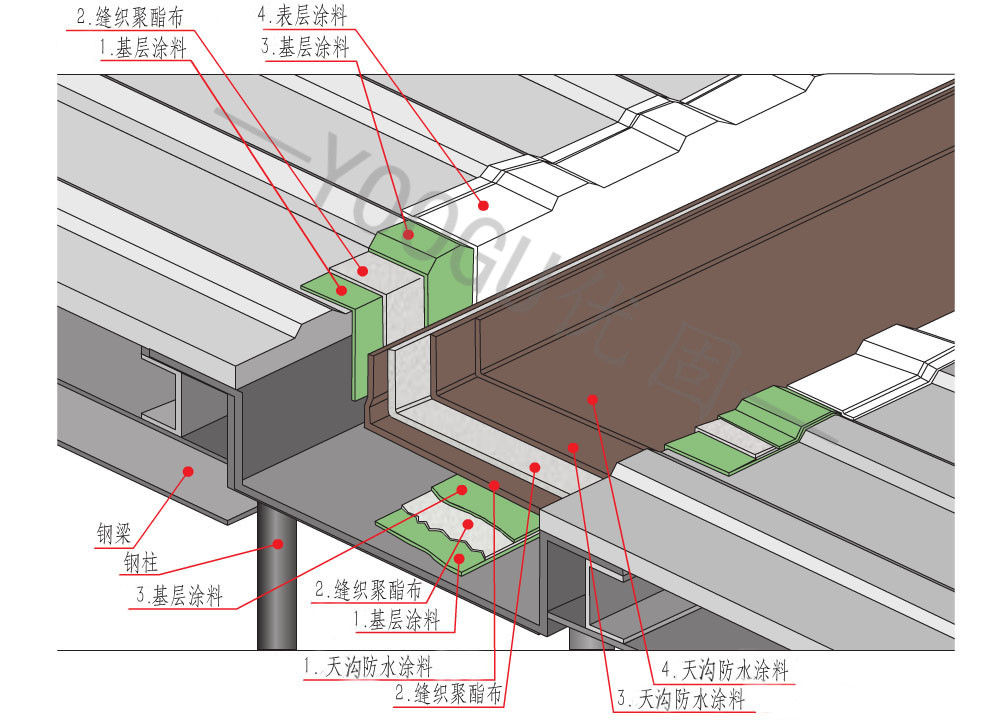

3.Yougu company gutter waterproof scheme and countermeasures

The figure below is a schematic diagram of the gutter waterproofing scheme of Yougu Company. The entire waterproofing system adopts the coating film waterproofing technology to form an overall seamless waterproofing system, which overcomes the seam problem existing in the waterproofing schemes such as coiled material.

4.Ugu's roof waterproof solution

Similar to the gutter waterproofing scheme, it also adopts the coating film waterproofing technology. Considering the severe weather environment of the roof, the single-component waterproof coating for metal roofing with strong weather resistance was selected. In addition to its good waterproof performance, it also has the characteristics of anti-ultraviolet radiation. The gap between the crest and bottom of the color steel plate is filled with low-foam plastic, so that the whole maintains a certain rigidity and flexibility, and can withstand the contraction and expansion of the bow of the cold and hot temperature difference. The method of applying I is basically the same as the above gutter waterproofing scheme, also adopting the process of three coats and one cloth.

Roof waterproof construction site map:

Company switchboard: 0755-89212007

Fax: 0755-89212007

E-mail: shili.yuan@yougufangshui.com

Company address: Qichuang Low Carbon Park, No. 1034, Longgang Avenue (Pingdi Section), Longgang District, Shenzhen