Building waterproofing scheme

The all-round waterproof way, an extraordinary waterproof experience.

It is suitable for anti-static places in industries such as electronics, communication, printing, computer room, precision machinery, powder, chemical, ordnance, aerospace and other industries. Especially suitable for the production workshop and storage area of electronic instruments, integrated circuits and other electronic components with high sensitivity to static electricity.

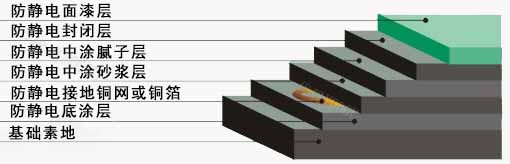

Modern industry continues to develop in the direction of automation and electronics.High-tech enterprises and key laboratories have extremely high requirements on the ground environment. Not only the ground has anti-static functions, but also the ground has high wear resistance and high impact resistance. Epoxy self-leveling anti-static floor coating system can meet such requirements, and realize the three-in-one combination of high wear resistance, high impact resistance and anti-static function. This system continues the excellent performance of the traditional self-leveling floor coating system, while adding conductive powder and surfactant to prepare a two-component epoxy self-leveling floor coating system, which can be very effective It can prevent static electricity from accumulating, and can discharge the accumulated static electricity brought by foreign objects through conduction and dissipation. It has the function of preventing static sparks.

1.The coating is automatically leveled and the surface is smooth and bright;

2. No seams, no dust, easy to clean the surface;

3. No solvent, environmental protection;

4.It can quickly leak static charge to prevent the destruction of electronic components and fire caused by the accumulation of static electricity;

5.The surface resistance is stable and durable, not affected by weather humidity and surface wear;

6. The dense surface can resist the erosion of many chemicals;

7. Various colors are available. Light color varieties, black fibers may be more obvious

In order to achieve the ideal use effect of epoxy resin anti-static flat coating floor, it is required to check the overall surface of the concrete base, comprehensive treatment of shelling, cracks, pits, looseness, oil stains, etc., so that the working surface To achieve the effect of leveling, drying and cleaning, then carry out the construction of epoxy anti-static floor project, so that the ground can achieve the effects of beautiful, dust-proof, anti-static, wear-resistant and pressure-resistant.

1. Check the ground and repair the cracks: Check the ground after the polishing is completed to see if there is loose ground falling off during the roughening process. If necessary, repair with epoxy mortar.

2. Grinding and vacuuming of the base surface: use a professional floor sanding machine to polish the base surface as a whole (finally make the epoxy floor and the ground tightly bonded together).

3. Clean the ground dust.

4. Determination of humidity: The "rubber pad test" uses a 1mx 1m polyZene film to be adhered to the concrete surface with adhesive tape (built-in dry paper towels). After 24 hours, it is removed and the amount of condensed water is determined.

5.Epoxy anti-static primer: The purpose is to close the surface, the primer penetrates the ground, so that the epoxy floor and the ground are tightly integrated (the primer mixes and mixes the main material and curing agent in proportion, and the base surface is painted, and the requirements are even. , No omissions).

6. Sweep the ground dust.

7. Lay copper foil: elastic wire (spacing 1mx1m) paste copper foil.

8. Epoxy anti-static intermediate coating: The purpose is to further repair, level the ground and prepare for topcoat construction. Mix the main material of the middle coat mortar and the curing agent in proportion, and mix it thoroughly. The mixing construction time is about 30 minutes. Use a toothed trowel to scrape it all over to make the surface smooth.

9. Light grinding and vacuuming of the base surface: Use a professional floor grinding machine to polish the base surface as a whole (finally make the epoxy floor better and more tightly bonded together).

10. Epoxy putty layer: the purpose is to further repair, level the ground, and prepare for topcoat construction. Mix the main material of the intermediate coating and the curing agent in proportion, and mix it well. The mixing construction time is about 30 minutes. Brush it once to make the surface smooth.

11.Epoxy anti-static flat coating surface coating: After the intermediate coating is cured, the construction area is closed, no unauthorized personnel are allowed to enter and exit, re-clean the ground, carefully check, remove surface particles, repair ground defects, vacuum with a vacuum cleaner, clean the ground for surface Tu construction. First mix the main material of the epoxy topcoat evenly, then add the curing agent to the main material barrel, mix it thoroughly, spray with a high-pressure airless sprayer, pay attention to the construction direction and construction interval, if the bottom coating of the mixing barrel is found to be cured When the block is used, you must stop using it and replace the mixing tank. After adding the curing agent, the top coat must be used within 30 minutes.

Company switchboard: 0755-89212007

Fax: 0755-89212007

E-mail: shili.yuan@yougufangshui.com

Company address: Qichuang Low Carbon Park, No. 1034, Longgang Avenue (Pingdi Section), Longgang District, Shenzhen