Building waterproofing scheme

The all-round waterproof way, an extraordinary waterproof experience.

It is suitable for various natural high or low temperature environments, such as industrial plants, logistics warehouses, stadiums, airports, stations and municipal public facilities. Suitable for complex structures composed of various substrates, such as concrete, wood, stone, hard plastic, glass, gypsum board, foam board, asphalt, rubber, SBS, APP, polyurethane, metal, etc.

YOOGU concrete high-elastic waterproof system is made of special acrylic environmentally friendly high-quality waterproof coating, supplemented by polyester cloth, and cured to form a complete seamless waterproof system for the roof.After hundreds of tests, processes, and formulations, it has been adjusted and optimized. Various test data of this product show that it has excellent resistance to alkali and acid rain, resistance to toughness, and has a very strong waterproof function, acid, alkali and salt resistance; excellent resistance to static water penetration pressure; good impact resistance, long-term anti-mold and antibacterial It is resistant to algae and has a long service life. It can prevent rainwater from channeling under the original waterproof layer, and it is rigid and flexible complementary to the base surface of various materials and has strong adhesion. This concrete roof waterproof system is the most advanced, economical and reliable high-elastic seamless waterproof system in China. This product is extremely convenient in construction and has a wide range of applications. It is a highly cost-effective, high-tech product that is urgently needed in the market; it has a very broad market prospect.

1. Excellent adaptability, can be directly constructed on a variety of material base and waterproof layer. The construction on the facade, slope and top surface does not flow.

2. It can be directly waterproofed on a variety of material bases and the old waterproof layer, and the curing speed is fast.

3. Especially has a very good anti-seepage effect on the back surface.

4. Strong hydrophobic additives are introduced into the formulation, and the coating interface has a "lotus effect" when it encounters water.

5. With weather resistance, tensile strength, tear resistance, flexibility, wear resistance, effectively adapt to the deformation and cracking of the base surface.

6. Make up for the defects of the yin and yang corner parts and the overlapping parts of the two materials that are difficult to handle with the coil material. It is strongly bonded to various base surfaces, and 100% is combined with the base surface to form a seamless waterproof layer.

7. It has excellent anti-static water penetration pressure; good impact resistance, long-term anti-mold, anti-bacterial and anti-algae properties.

8. With aging resistance, corrosion resistance, rolling resistance, tough coating, high strength and high elasticity, service life is more than 15 years.

Base surface pretreatment:

Carefully clean the I-base surface during construction. It must be ensured that the base surface is flat, the firmware is free of looseness, no rust, no oil, no dust, and no clear water to keep it clean. Firmware with loose base surfaces must be replaced or reinforced.

For the uneven base surface, thicken the cement paste, level it with a batch knife-times, the thickness of the block is less than 5mm, please note that the block should not be too thick every time, the cracks need to use this product as an additional layer. The arc processing of the hard seat at the Yin-Yang corner, the wall-penetrating pipe, the water outlet and other complex parts also need to be treated with additional layers.

Construction preparation:

Determine the parts to be waterproofed and the width of the waterproof layer, and cut the polyester cloth of corresponding width.

The paint needs to be stirred evenly when it is used, but no additional water or auxiliary materials are needed, and it can be applied directly.

During construction, brushing, rolling and scraping can be carried out. Related working tools should be prepared and necessary measures for labor protection should be done.

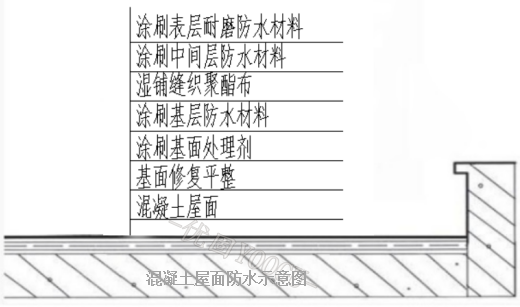

Concrete acrylic high elastic flexible material three-coat one cloth waterproof construction process:

1. The water-proof coating is evenly mixed according to the ratio, and the base surface is cleaned up to make the base surface smooth, dust-free and water-free oil.

2. Brush the base layer (one coat): on the cleaned base surface, apply the acrylic high-elastic base layer waterproof coating on the concrete roof (function: used to bond with the substrate to achieve 100% continuous full adhesion).

3. Laying seam-woven polyester cloth (one cloth): When it is still wet, lay the cut silk-woven polyester cloth in it.

4. Brushing the base layer (second coating): immediately paint the acrylic roofing base layer waterproof coating of the concrete roof on the surface of the silk woven polyester cloth, so that the slurry can fully infiltrate the silk woven polyester cloth to ensure that there is no drum, No wrinkle, so that the slurry can fully combine with the bottom slurry through the gap of the silk-woven polyester cloth to become a seamless whole, even dry.

5. Brushing the surface layer (three coats): after the upper layer is dried and solidified, then apply a layer of acrylate concrete roofing acrylic high-elastic waterproof coating (the protective layer can choose high elasticity, abrasion resistance, thermal insulation and other functional surface layers) ).

Construction instructions:

1. Reference dosage: the basic coating is coated with a theoretical 40㎡/20L; the actual utilization rate of the silk-woven polyester cloth is 90%; the theoretical coating with the surface coating is 55㎡/20L. The actual consumption of consumables depends on the application conditions and substrate conditions.

2. Construction tools: agitator, hard bristle brush (wool brush is not available), scraper, roller, etc. Wash with clean water immediately after construction.

3. Construction environment: This product is suitable for construction at a temperature of 5°C ~ 45°C and a humidity of less than 85%. It is not suitable for construction when it exceeds the environmental conditions. It is not advisable to apply I under severe weather conditions such as rain, snow and ice fragrance. Please pay attention to the weather forecast in advance.

4. Note: Due to weather or substrate material, if the coating is too thick and difficult to apply, it can be diluted with an appropriate amount of water.

Company switchboard: 0755-89212007

Fax: 0755-89212007

E-mail: shili.yuan@yougufangshui.com

Company address: Qichuang Low Carbon Park, No. 1034, Longgang Avenue (Pingdi Section), Longgang District, Shenzhen